新闻中心

意德拉的宗旨:不断成长、开发新策略及生产世界最大型压铸机!

Idra Thinks Big: Growth, New Strategies and an Order for the Largest Press in the World.

意德拉的宗旨:不断成长、开发新策略及生产世界最大型压铸机!

by Mario Conserva

General Manager Riccardo Ferrario announces the development lines for the next few years based on synergies with shareholder LK Machinery and product development: the new X-Press machines at highly competitive prices and the extension of the upper bracket OLCS range with 5500 and 6200--ton models.

意德拉总经理Riccardo Ferrario与LK集团的携手合作,宣布了其公司及产品发展路线,以极具竞争力的价格生产新型X-Press机器,并扩展了OLCS系列至5500吨和6200吨。

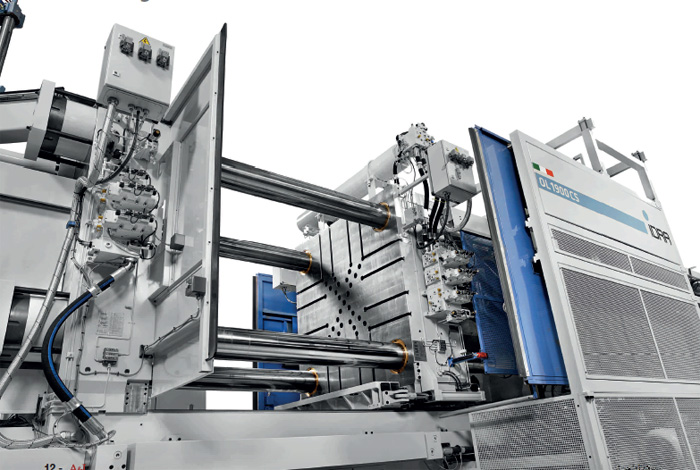

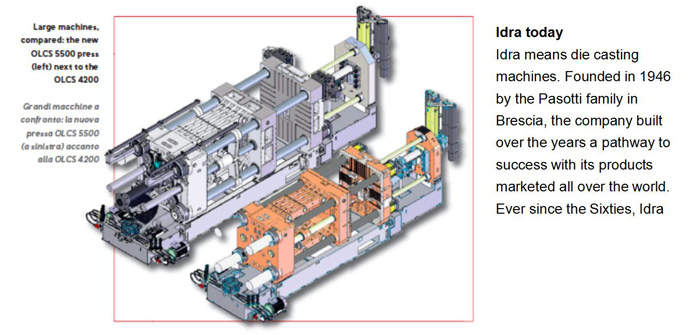

We met Riccardo Ferrario, Idra’s general manager, at the plant in Travagliato (near Brescia), to exchange views on the production and market situation of the die casting segment, on its out- look given the complex global scenario and of course to sum up the state of Idra. This was the starting point, and Ferrario announced for the first time the production and marketing strategies of the Brescia-based company for the next few years: “Idra is in excellent shape, we would like to consolidate the good results of the past few years, but also to pursue the aim of increasing turnover by 20% in the short term and for this reason we defined new strategies with the control shareholder, LK Machinery. The plan is al-ready operational and it involves the new line of machines, X-Press, at particularly competitive prices for the production of standard die castings, and at the other end of the range the “Giga presses”, 5500 and 6200, and a series of deep innovations on our upper bracket OLCS machines, with changes in the injection and energy saving systems and an aesthetical rationalization”.

我们在特拉瓦利亚托(布雷西亚附近)的工厂采访了意德拉总经理Riccardo Ferrario先生,就压铸部门的生产和市场状况交换意见,就目前全球的复杂形势总结了意德拉的状态。Riccardo Ferrario首次公布了布雷西亚公司未来几年的生产和营销战略,这只是一个开始。

“意德拉状况良好,我们希望在加强巩固过去几年良好状态的同时追求在短期内将意德拉的营业额增加20%的目标。为此,我们与LK公司制定了新的战略。该计划已经开始运作,它涉及到新的机器生产线。X-Press系列,以极其具有竞争力的价格生一系列产品标准压铸件。另一方面,我们对Giga Press 5500和6200系列以及OLCS压铸机进行了深度研发,就压射系统和节能系统进行了优化以及美观上更加合理化。

The general manager of Idra opened the meeting with A&L magazine, in his friendly and pragmatic style, with a rapid introductory exchange, but a very meaningful one, both for the Brescia-based company and for the global die casting system, on the eve of such a relevant event for this segment as Gifa 2019. Ferrario added: “The project we worked on for Idra’ s future stems from a careful series of considerations regarding various factors, such as, the macroeconomic picture, our market segment, the company’s previous trends, our relationship with the control group; I shall try to offer in the most synthetic and clear way the necessary details”. It is however worth providing, to start with, an updated general picture of the company.

以一贯友好务实的方式,意德拉总经理与A&L杂志召开了会议。双方进行了快速的沟通。此次会议对于布雷西亚公司和全球压铸领域来说是一个非常有意义的会议,类似活动如2019年的GIFA。Riccardo Ferrario先生补充道:“对于意德拉,我们所做的项目都是经过一系列的深思熟虑,例如,宏观经济形势、我们的市场细分、公司的过往趋势、以及我们与控股集团的关系。我们力求以最综合、最清晰的方式提供必要细节。为此,提供公司的最新概况是值得的。

Idra today

Idra means die casting machines. Founded in 1946 by the Pasotti family in Brescia, the company built over the years a pathway to success with its products marketed all over the world. Ever since the Sixties, Idra was a reference point in the industry, trade operators remember well when the legendary “S” series represented the utmost reliability, strength and user-friendli-ness. With the ups and downs typical of the market, the early 2000s were a critical moment for Idra, with a phase of restructuring and downsizing of the industrial perimeter and the number of employees; however the strength of its entrepreneurial history, know-how and human capital built up over the years allowed the company to overcome these difficulties, the first decisive element in 2008 was the acquisition of the company’s majority package by the Chinese group, LK Machinery, an industrial giant listed on the Hong Kong stock exchang and market leader in China for light alloy die casting machines, injection ma-chines for plastic components and work stations for mechanical machining The second key element was the new general manager Riccardo Ferrario, who joined the company in the following year, an engineer with a deep knowledge of business management and with twenty years of experience in metallurgy accrued working for Fiat, in the aluminum casting foundry of the TEKSID group headed by Professor Sergio Gallo. The change of pace gave its strength back to the glorious Idra brand, which once more represented an excellent example of industrial reality: the company succeeded in reaching its break-even point in only 18 months, eliminating a loss of almost 8 million euro and starting to produce earnings as early as 2011; sales rose from 14 million euro in 2009 to 57 million in 2012, for the past four years consolidated revenues have varied from 85 to 95million euro. Idra thereby went back to the top of the segment’s global ranking, a leader especially in large, high-technology die casting machines for high performance castings.

今天的意德拉

意德拉意味着压铸机的历史。于1946年由布雷西亚的帕索蒂法米利(Pasotti Family)创立,多年来一直致力于产品在全球市场上的成功。60年代以来,IDRA一直是业界的一个标杆,众多贸易运营商应该很清楚地记得。传奇的“S”系列产品代表着最高的可靠性、实用性和用户友好性。21世纪初对IDRA来说是一个关键时刻,市场起伏动荡,行业范围以及员工数量的重组和缩减,然而其创业历史、专业技能的优势以及多年来积累的人力资源使公司克服了这些困难。

2008年第一个决定性因素是中国集团LK机械收购了公司的多数股权,LK机械是香港证交所上市的工业巨头,中国市场领先的轻合金压铸机、注塑机和机械加工设备厂家。第二个关键因素是新的总经理里卡多·费拉里奥(Riccardo Ferrario),于次年加入公司,他是一名对企业管理有深入了解的工程师,具有20年的压铸经验,在菲亚特(Fiat)和Sergio Ga教授领导的TEksid集团的铝铸件铸造厂积累了丰富的经验。步伐的改变使IDRA品牌实力回到了辉煌的时刻,公司在短短18个月内就成功地达到了收支平衡点。这再次验证了工业领域的一个极好例子。公司因此消除了近800万欧元的亏损,并于2011年开始盈利;销售额从2009年的1400万欧元增至2012年的5700万欧元,过去四年的综合收入从8500万欧元增至9500万欧元。因此,IDRA又回到了行业全球排名的首位,尤其是在高性能铸件的大型高科技压铸机领域处于领先地位。

Riccardo Ferrario’s analysis

“To explain our objectives I think it might be useful to de-scribe briefly the main lines of action which we followed in the recent past, starting from the end of 2008 when I was contacted to relaunch Idra which, on account of financial issues, was not going through a good period. I remember the decisive meeting with Mr. Liu, the founder and largest shareholder of LK Machinery, the company which had just acquired 70% of Idra’s share capital, while the rest was in the hands of Banca San Paolo. Liu was an entrepreneur with very clear ideas, he wanted to be the leader not only in the segment of low cost presses on the Chinese market, but he also intended to develop a leading presence on the entire product range, and he wanted Idra to preside the segment of high-technology presses for high performance die castings. In order to do this it was necessary to set the two brands clearly apart, LK for low cost machines and Idra for upper bracket solutions; no type of contact between the two concerns, not even on a distribution and financial level, the market had to understand clearly that LK was just a shareholder. Subsequently shareholder LK purchased the remaining 30% and the company became completely Chinese, but the initial strategies remained unaltered in their essential lines”.

Riccardo Ferrario先生的分析

“为了更好地诠释我们的目标,我认为简要描述一下我们在圣保罗银行(Banca San Paolo)掌控期间遵循的主要行动方针可能会有所帮助。刘先生是一位有着非常清晰想法的企业家,他不仅想在中国市场上成为低成本压力机领域的领导者,而且还想在整个产品范围内发展出领先的地位,他还想让IDRA在高性能压铸件的高技术压力机上成为行业佼佼者。为了做到这一点,就有必要将这两个品牌明确区分开来,LK提供中低端的设备方案,IDRA提供高端的解决方案;市场必须清楚地了解,这两者并没有任何联系,甚至在分销和金融方面,LK只是一个股东。随后LK收购了剩余的30%,公司的背景性质则为中国企业,但最初的战略和基本路线上并没有改变。

What concrete effects did the arrival of LK bring about?

“The initial project envisaged in 2008 for Idra worked out well, China represented salvation. The leading shareholder invested in the company as agreed, allowing us to complete the development of the new OLCS model, and furthermore we were served the keys of the Chinese market on a silver platter, with indications as to where and to whom to sell our products in such hard years as 2009 and 2010. Without this help we would not have had the speed necessary to bring the accounts back two years, in spite of the great efforts which we made internally to keep a lean and flexible structure capable of adapting itself to the different moments of the market. On the other hand, the asset of Idra’s know-how guaranteed the creation of cutting-edge products; what could have been difficult to fill was perhaps thecompetitiveness gap regarding costs. Luckily I come from the formidable Teksid school of the ‘80s and I know that nothing happens by chance, but that everything must be conquered with fierce determination and strong passion, starting from people. This is the premise to explain what we were like just ten years ago, how we overcame difficulties and what objectives we reached, but it is clear that times have changed, this is why we now need a different project.”

LK的到来带来了什么具体的影响?

“2008年为IDRA设想的初步项目进展顺利,中国代表着拯救。主要股东按照约定对公司进行了投资,使我们能够完成新的OLCS系列的开发,由此才得到开启中国市场的钥匙。迹象表明,在2009年和2010年这样艰难的年份里,我们的产品在哪里销售,销售给谁。如果没有获得帮助,我们没有可能在不到两年的时间里恢复平衡,尽管内部做出了巨大努力去保持一个精简和灵活的结构以适应不同的市场形势。而另一方面,IDRA的专有技术资产保证了先进产品的创造;但难以填补的是成本竞争力上的差距。幸运的是,我来自80年代的颇有声望的Teksid公司,也知道没有任何事情是偶然发生的,但必须以强烈的决心和热情征服一切,从个人做起。这也解释了十年前我们的处境、克服困难的方式和实现目标的前提,但很明显时代已经改变,这就是为什么我们现在需要一个不同的项目。”

Looking at the outlook of your reference markets, which considerations may be inferred regarding the demand of quality die castings by the automotive industry during the next few years? And for segments with less performing product requirements, what forecasts may be suggested?

“The direction which the market will take is definitely the main issue to be examined in order to understand which decisions should be made. To begin with, let us consider where our market is and what it has become today; everything changed in a matter of a few years. The growth in the use of aluminum details and components in transportation underwent a dramatic trend in recent years, because it is a light weighting which pays itself back.

从市场参考的前景来看,在未来几年内,汽车行业对优质压铸件的需求有哪些考虑?对于产品需求表现不佳的细分市场,可以建议哪些预测?

“市场的方向无疑是需要考察的主要问题,以了解应该做出哪些决策。首先,让我们考虑一下我们的市场在哪里,以及今天的情况;几年后一切都会发生变化。近年来,铝合金零件和组件在使用量上出现了显著的增长趋势,而这源于轻量化的发展。

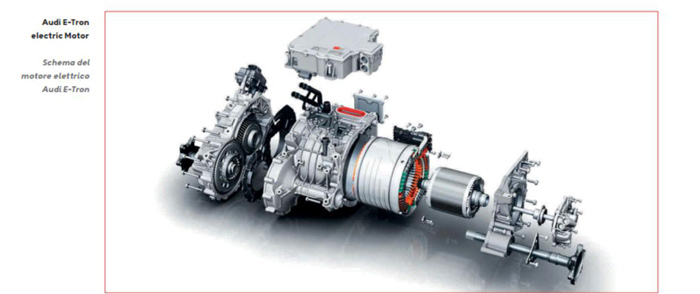

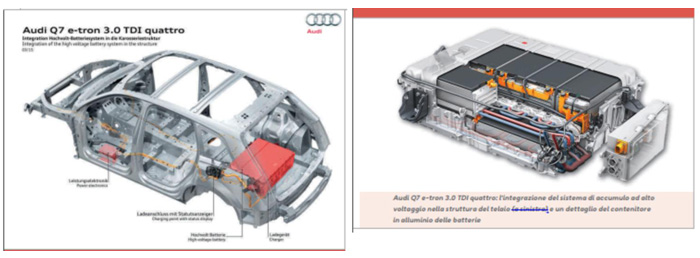

The growth in the use of aluminum details and components in transportation underwent a dramatic trend in recent years, because it is a lightweighting which pays itself back. In Europe the average aluminum content per vehicle was 50 kg in 1990 and should add up to more than 200 kg in 2025. A highly significant datum in this development is the opening of new, completely innovative areas, right up to a few years ago normal aluminum castings were limited to motor blocks, pistons, crankcases, wheels; today we are talking about thin structural castings, with a development which of course does not only concern castings, but is also referred to sheet metal for car bodies and structural extrusions in light alloys. This trend implied, for the upper bracket of the die castings market, a new generation of presses characterized by performance requisites which would have been unthinkable just a few years ago: designed to be inserted in production cells with the highest level of perfection and automation, suitable for functioning with sophisticated and metallurgical innovative alloys, distributed on the global scenario in terms of completely different factors with respect to those operating a few years ago.

近年来,在汽车上使用更多铝合金件的增长呈现出戏剧性的趋势,因为这是一个汽车轻量化的回报。在欧洲,每辆汽车上铝合金铸件使用量,在1990年时是50公斤,预计在2025年应该会超过200公斤,该数据已表明铝合金铸件广泛使用开启了一个全新的,具有创新性领域。过去几年,常规铝合金件仅仅应用在汽车缸体,传动系统,变速箱体和车轮。今天我们讨论的是薄壁结构件,它的发展当然不仅涉及铸件,而且还涉及汽车车身的金属板金件和轻合金结构挤压件。该趋势意味着:在压铸市场的高端领域,要求新一代压铸机自动化程度非常高和柔性非常好,适合生产功能复杂和创新性合金压铸件生产,在过去几年是无法想象的。为全球压铸技术发展做出杰出贡献。

The car market has always continued growing during the past few years, ecology speaks up louder than ever especially in the large automotive districts in Europe and in China, helped along by political and social values which created a practically unanimous consent regarding the limits on emissions. This allows to forecast an increasingly fast race towards lightweighting and therefore the use of a growing amount of light alloy die castings; independent of the type of driving force, the choice of aluminum may not be reversed, at least in the short term, because it is a reasonably winning choice, it is a fact that even the car manufacturers who are more opposed to change have resorted to using light metal die castings for the new petrol engines and for the chassis.

在过去的几年里,汽车市场一直在持续增长,在政治和社会价值观的帮助下,生态环境要求比以往任何时候都更高,尤其是在欧洲和中国的大型汽车区更为严格。一致同意提高尾气排放标准。汽车轻量化步伐加快,因此压铸轻合金的使用量逐级增加。除了各种外在因素,选择更多铝合金应用在汽车上,至少在短期内也是一个理由充足、双赢的结果。事实上,即使汽车制造商更多地反对改变,但他们已经在新的汽油发动机和传动系统中使用了很多轻合金压铸件。

In this respect, to conclude, I believe that the car market will keep on growing, looking at the most advanced products and demanding increasingly extreme performances from the light alloy details, most of which will be die castings. Of course, composite materials could replace the light metal in many applications with further advantages on lightweighting and perhaps even with design simplifications, but the issue of costs and, above all, the serious handicap of composites lined to their difficult recyclability remain open. In this domain it is very difficult to compete with aluminium, a splendid green metal and synonym of circular economy. Basically I believe in the continuity of the market which enabled us to grow so far. Regarding standard die castings, it is clear that the use of aluminium castings without particular structural requisites will grow physiologically and everywhere. We therefore also foresee a growth in the global demand for standard die castings, to be created with low cost machines, which today are not part of Idra’s offer, but which in consideration of the volumes at stake we think we should consider very carefully in the near future

在该领域总结如下:我相信汽车市场会继续保持增长,查阅最先进的产品,对轻合金的杰出性能要求非常高,更多的还是选择压铸件。当然,复合型材料在汽车轻量化使用中可能会比轻合金更加合适,设计更加简单。但是不得不考虑成本,总之,复合型材料的回收还有待解决,在汽车领域的优势不如铝合金-绿色金属、可回收、更加环保。我基本相信压铸市场的可持续性发展使我们可以长远发展。考虑压铸件标准,使用没有特别结构要求的铝合金压铸件增长速度非常快,使用更广泛,这一点是非常明确的。因此,我们也会预见全球对压铸件的需求,将会在运行成本最低的压铸机上生产,意德拉也是其中受益者之一,但是我们也不得不考虑未来的需求量。

What about Idra, in what situation is it today? 意德拉如何?意德拉的形势?

“We emerged in good shape from the difficult period, the choice of consolidating our upper bracket market worked, we so far focused on powerful and sophisticated machines for a demanding market such as the automotive industry, we were the first to build machines for structural elements, we bravely decided to invest in this direction in the middle of the crisis six years ago and today we produce the largest machines in the world, 5500 ton and 6200ton presses.

Recently we received the first order in the world for a 5,500 ton press, we are particularly pleased with our success and we believe that other orders will follow shortly. Even in this case we started off first on these projects which seemed to be impossible and now we can deliver Giga presses in standard times. Our revenues have reached around 100 million euro for four years now, in an expanding market where we must therefore grow, we think we may aim at a growth in our revenues of about 20% to allow a correct consolidation of the industrial progress of the past few years. Producing more in order to sell more, exploiting our know-how to provide the market with the right product at the right time, therefore endeavouring to make our presses increasingly smart, so as to provide the user with the possibility of realizing an increasingly competitive product”.

我们已经走出最困难时候,现在发展势头良好,牢固占领高端压铸市场。目前我们把主要精力集中开发、制造功能强大、坚固耐用的压铸机,满足市场需要,例如汽车市场,意德拉是第一家为设计开发专用压铸机,用于生产汽车结构件。在6年前还处于危机的中期,意德拉大胆地决定大力投资发展结构件压铸机。今天,我们研发世界上最大吨位压铸机5500吨和6200吨。最近我们已经接到了第一个5500吨压铸机订单,我们深感自豪!我们相信最近陆陆续续会接到其他订单。项目刚开始困难重重,成功希望渺茫,最终已成功,我们也会把成功经验在GIFA展会上与客户分项。我们的年营业额已经连续4年超过1亿欧元,意德拉在压铸市场快速扩张中进行成长。我们目标是保持20%的年营业额增长,基于对过去几年压铸市场的正确巩固。生产并销售更多压铸机,利用我们的压铸专业技术给客户在正确时间提供合适的产品。因此,保持压铸机销售稳健增长,为客户提供竞争力更强的压铸装备。

What guidelines do you intend following to reach your aim?

你打算遵循什么样的指导方针来达到你的目标

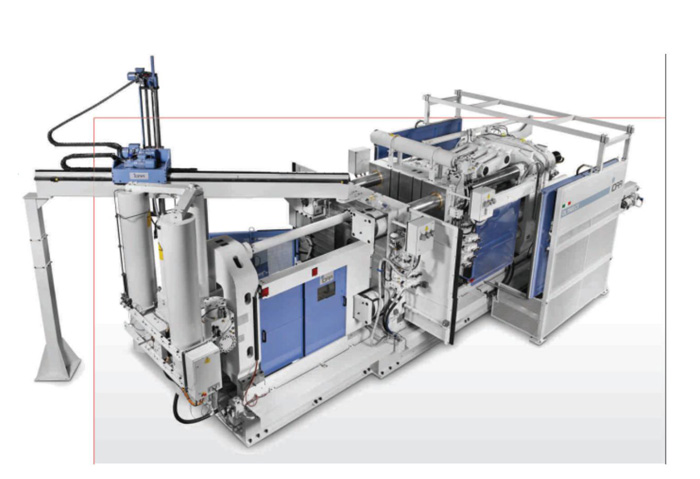

“The first change of direction concerns the relationship with LK Machinery. Until now the group acted as a pure shareholder; from now on, besides helping us to secure more orders in China, it will provide us with production capacity for the new X-Press machines, press models with up to 900 tons of clamping force. The aim is basically stepping in with Idra machines, that is, with a product which is extremely interesting from a technological and performance standpoint, in the segment of medium to small presses, offered at extremely competitive process, and this is enabled, without costly investments, by exploiting the capaity available at LK.

第一个方向变化与LK关系有关,过去LK一直以纯股东方式管理意德拉。从现在起,LK除了帮助我们在中国市场寻找更多订单,还帮助我们生产X-Press压铸机,最大锁模力达到900吨。目标是把意德拉压铸技术,杰出的性能特点融合至X-Press中小型机型,以提高其工艺竞争能力,在不增加任何成本投入情况下,利用LK富裕产能进行生产制造。

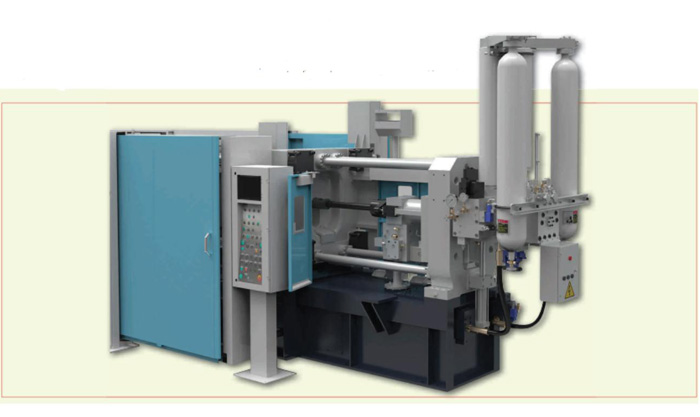

X-Press machines are totally designed and produced following the guidelines of upper bracket models and will have the reliability of Idra products at competitive prices, 30% less than OLCS models. This will not imply any negotiation on the quality and reliability of the product; it will just be thought of as a standard, with high volumes and produced in the LK plant in Shenzhen, in an area totally dedicated to us. Let us for instance think of a 500 ton machine, suitable for the production of die castings with no special structural demands, offered in its standard version, therefore without any sophisticated customizations, but qualitative, since it will have the same injection and clamping systems as OLCS and it will benefit from many of our innovations developed for the upper bracket range.

X-Press压铸机完全按照高端压铸机进行设计、生产制造。具有意德拉压铸机的可靠性特点,非常有竞争力的价格,比OLCS价格便宜30%以上,但在品质和可靠性上不打任何折扣。将会考虑标准化,批量化在LK深圳工厂指定车间进行生产。以500吨压铸机为例,适合生产的压铸件无任何特殊结构要求,标准机型,因此不需要任何定制化要求。但是,品质来源于OLCS同样的压射系统和合模系统,适合于生产很多高端压铸产品。

I would like to add that in the typical market segment for X-Press machines the do-it-yourself concept works well; users in this segment like basic standard machines very much since they can enrich them gradually in-house depending on contingent demands, and I must say that in this respect the fact that Idra is part of Foundry Star Alliance, recently joined by a new partner, is definitely a very positive element for our clients who may count on an extraordinary technical knowledge available for them.

我想指出的是:X-Press机型采用全自动化、标准化概念。在该段机型中客户更喜欢标准化,因为客户可以根据需要,逐渐丰富功能。我必须指出意德拉是压铸联盟重要成员之一,该联盟最近成立,对需要得到综合技术咨询和指导服务的客户至关重要。

For us here at Idra this is an interesting challenge on a relatively uncharted territory, we are pursuing it with intent and determination, we already tested the market with about ten machines sold in China, Brazil and Mexico, the response has been very positive, we trust that this choice will represent the fundamental tool to reach our objective of 120 million euro revenues. Regarding the upper bracket range, OLCS, here our interventions aim at the continuous improvement of the machines, exploiting in depth and with continuity the great wealth of knowledge accrued in Idra. We are aiming at significant innovations which concern several essential aspects of performances:

对我们来说,这是一个有趣的挑战,在一个相对未知的领域,意德拉正在尝试和努力提高。我们已经在市场上投放了近10套压铸机,销售给中国、巴西和墨西哥客户,反应非常积极。我们相信,这一选择基本可以实现我们1.2亿欧元年销售目标。关于高端压铸机市场,我们将继续改进OLCS压铸机,更深入探索技术,持续开发,积累丰富的意德拉压铸技术。我们计划在以下几方面进行创新:

• new solutions for the hydraulic plant, capable of determining a certified 40% saving on energy consumption; 在液压系统探索新方案,节省40%以上能源消耗

• more stable injection conditions in all phases, so as to guarantee the best possible dynamic force in every possible operating phase and therefore the possibility of manufacturing larger structural castings with thinner walls; 压

射全过程更加稳定可靠,提供最佳动态压射力,保障生产投影面积大、薄壁结构件性能更稳定

• a deep evolution in the body of cars, doors and protection, improving aesthetics and modularity;

车身、车门和汽车防护件的深度开发,提高美观性和模块化程度

• as regards Industry 4.0, development of new architectures for the die casting cell with a central control hub monitoring the press and all other peripheral equipment, so as to ensure the central role of control programming and the simplification of the commissioning of machines at the clients’ premises.

工业4.0方面,持续开发压铸单元新的构架系统,集中控制系统监控压铸机和周边设备,控制程序集中化,在客户许可情况下设备之间通讯简单化

I think this should provide in a precise summary the message that Idra is more than ever alive. We are working on a very challenging series of innovations which concern the structure of the company’s industrial operations, the growth and diversification of the technological content of our machines, the way we approach the global market. We are aligned with our long-standing objective, helping the foundry to change and being increasingly science as well as art; it is difficult to do so on our own, today more than ever the support of our shareholder LK Machinery is essential, as they always interpreted well the best role that Idra could have within the group. At the same time I would like to stress the importance of a collective initiative such as Foundry Star Alliance in order to be equipped in the best way to renew our technologies. This has proved to be a bold and effective operation which created important synergies among leading suppliers of complementary plants and equipment for presses enhancing the value of the industry, it worked and it will be increasingly useful in the future”.

我认为准确的总结信息如下:IDRA比以往任何时候都更活跃。我们正在致力于一系列极具挑战性的创新,这些创新涉及到公司的工业运营结构、压铸机技术含量的增长和多样化,以及我们接近全球市场的方式。我们一直努力向长远目标靠近,帮忙压铸厂不断改变,丰富压铸科学和艺术。意德拉单兵作战比较困难,今天我们的股东LK给予了比以往更多的支持,LK不断诠释IDRA在集团中的最佳角色。同时,我想再次重申集体倡议的总要性比如压铸之星联盟,更新技术的最好途径。事实证明,这是一项大胆创新而有效的行动,在主要的压铸厂和配套设备供应商之间产生了重要的协同作用,提高了压铸行业的价值,压铸联盟之星的作用在未来将越来越有用。”